Quartz Glass

UV-Grade Fused Silica for optical applications

Special Properties

- Excellent UV transmission

- High optical quality

- High-purity glass composition

- Extremely heat-resistant

- Low coefficient of thermal expansion

- Crystal-clear, water-white appearance

- Operating temperature of up to 1000 °C

- Very high thermal shock resistance

- Excellent chemical resistance

- Low fluorescence

- High electrical insulation properties

- Chemically inert

- Made by a flame hydrolysis process

- Machinable by cutting, grinding, and polishing

Typical Applications

- Ultraviolet and deep UV (DUV) transmitting windows

- Glass wafers for semiconductor technology

- Substrates for mirror or filter coatings

- UV measurement instruments

- Microscope slides and coverslips for medical applications

- Industrial quartz products

- High-temperature applications

- Chemically resistant glass components

- Pressure windows

- Quartz plates for laboratory equipment

- Space Technology

Related Glass Types

- BOROFLOAT®

- (Borosilicate Glass from SCHOTT)

- Natural Quartz Glass

(Fused Quartz for Sight Glass Applications)

Optical Quartz Glass | Synthetic Fused Silica

Optical quartz glass is a synthetic, high-purity fused silica produced by a flame hydrolysis melting process.  The crystal-clear amorphous silicon dioxide material contains virtually no impurities, consisting only of silicon and oxygen. This unique grade of quartz glass provides over 80% UV light transmission at a wavelength of 185 nm.

The crystal-clear amorphous silicon dioxide material contains virtually no impurities, consisting only of silicon and oxygen. This unique grade of quartz glass provides over 80% UV light transmission at a wavelength of 185 nm.

The enormous operating temperature range and thermal endurance of quartz glass are unparalleled. It can operate continuously up to 1000 °C and is highly resistant to thermal shock due to its very low coefficient of thermal expansion. Moreover, the chemical properties of quartz glass are remarkable. Its chemical resistance to acids exceeds that of almost all other glass materials. Quartz glass is durable and exceptionally resistant to salt solutions, alkalis, and water.

Due to its excellent electrical properties, quartz glass is ideal for semiconductor applications. Because currents can only flow through mobile ionic impurities that are marginally present in quartz glass, it offers exceptional electrical insulation, which is essential for many electronic devices and semiconductors.

Quartz Glass Optics

We manufacture custom optics for the UV, visible, and infrared wavelength ranges, primarily from large quartz blocks, called boules. We can select the raw glass for inclusion and bubble classes. Moreover, an index homogeneity level down to ≤ 0,5 ppm is available if this is critical. Cutting the raw material from the boule is the first step in the production of a quartz glass optic. After this process, the quartz glass is shaped and finely ground, and the surface is polished according to the specific requirements. In this way, our company produces UV-transparent substrate glasses, glass wafers, microscope slides, and many other quartz glass products on a daily basis.

How do I get a quote?

To request a quotation for windows, substrates, glass plates, or other optical quartz glass parts with custom dimensions, please select a material from the table or use the button below.

Specifications and Properties

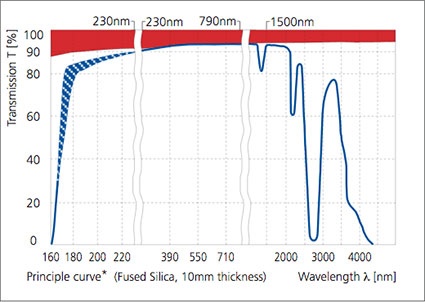

Transmittance spectrum of synthetic

fused silica in the ultraviolet-to-infrared rangeGlass Thicknesses

As high-purity fused silica is a block glass, there are usually no standard thicknesses available off-the-shelf. The thickness must therefore be individually specified and manufactured. However, we continuously grind and polish to different thicknesses and tolerances to offer our customers the best availability. You can even order these with individual dimensions and take advantage of our 48-hour express production.

Click on a thickness to start an inquiry:

Glass THK |

Tolerance |

|

|---|---|---|

| 0,175 | ±0,020 | ✔ |

| 0,30 | ±0,050 | ✔ |

| 0,30 | ±0,025 | ✔ |

| 0,50 | ±0,050 | ✔ |

| 0,50 | ±0,030 | ✔ |

| 0,50 | ±0,025 | ✔ |

| 1,00 | ±0,100 | ✔ |

| 1,00 | ±0,025 | ✔ |

| 1,10 | ±0,100 | ✔ |

| 2,00 | ±0,150 | ✔ |

| 3,00 | ±0,200 | ✔ |

| 3,00 | ±0,025 | ✔ |

| Other thicknesses are possible on demand. | ||

Light Transmission

- T > 80% at 185 nm

(UV-grade material = fused silica)Refractive Index

- nd = 1,4585

Density

- 2,20 g/cm3

Young's Modulus

- 74 GPa (typical value)

Homogeneity

- Homogeneity classes per inquiry

- Index homogeneity of the UV class materials down to ≤ 0,5 ppm is possible on demand

Inclusion Classes

- Inclusion-class options on request

Glass Composition

- Silicon Dioxide (SiO2)

Operating Temperature

- Up to 1000 °C

Average Coefficient of Thermal Expansion

- ≈ 0,57 × 10-6/K

Viscosity

- Softening point ≈ 1585 °C

- Annealing point ≈ 1042 °C

- Strain point ≈ 893 °C

Dielectric Constant

- εr: 3,9 (500 MHz)

Fused Quartz for Sight Glass Applications

In addition to the high-grade quartz glass described above, we also process a less sophisticated quartz material called fused quartz. Although it is also called quartz glass, it is quite different from the optical-grade materials. Unlike fused silica, this material is made by melting natural quartz crystals. As a result, fused quartz contains far more impurities and can't offer the homogeneity or outstanding optical performance of fused silica. These lower material grades are typically used for high-temperature applications where only sight glass quality is required. As internal material purity and deep UV transparency are of secondary importance in such use cases, this more economical quartz glass material is the best choice for such components.

Although fused quartz glass is only suitable for less demanding applications, it has an almost identical coefficient of expansion, a similar heat resistance, and the same good thermal properties as the higher-grade materials. It also has excellent chemical resistance and offers better UV light transparency than most other glasses. Furthermore, it offers very high infrared transmission and the same crystal-clear appearance as optical quartz.

Fused quartz is ideal for the fabrication of high-temperature sight glasses, lamp housings, UV lighting systems, clear furnace glasses, pressure-resistant windows, and other industrial quartz glass components. For further details, specifications, and properties, please refer to our Fused Quartz datasheet.

Our company processes raw materials from leading manufacturers in the quartz glass industry (Corning, Heraeus, Tosoh, SCHOTT, Saint-Gobain Quartz, Shin-Etsu, GE Quartz, and many others). More detailed properties, datasheets, and information on all glass qualities we supply are available on request.

All details and specifications given are average reference values and are not guaranteed. Please consider the "Notes on technical specifications".

© 1994 – 2024 Präzisions Glas & Optik GmbH

Last update: May 06, 2024